Best Quality CNC Fiber Laser Cutting Machine - 5 Axis 3d Double Station Mould Processing Cnc Router – FELTON

Best Quality CNC Fiber Laser Cutting Machine - 5 Axis 3d Double Station Mould Processing Cnc Router – FELTON Detail:

Configuration

| item | name | number |

| Taiwan SYNTEC SYSTEM | 1 | |

| X axis SYNTEC 1KW servo motor | 1 | |

| Y axis SYNTEC 1KW servo motor | 2 | |

| Z axis SYNTEC 1kw servo motor | 1 | |

| 9kw HQD water cool spindle | 1 | |

| X axis M2 grinding gear rack | 1 | |

| Y axis PMI—4040 high accuracy ball screw | 2 | |

| Z axis PMI—3210 high accuracy ball screw | 1 | |

| X axis 30 linear guide rail | 3 | |

| Y axis 30 linear guide rail | 4 | |

| Z axis 30 linear guide rail | 2 | |

| FULING 11KW frequency governor | 1 | |

| 13 . T slot aluminum station | 4 | |

| Work area 1220x2440mm | ||

| Central air storage system | 1 | |

| Central lubrication system | 1 | |

| Fast change tool | 8 | |

| Spring fixture | 1 | |

| Check list | 1 | |

| Quality paper | 1 | |

| Water pump | 1 |

Parameters

|

name |

parameter |

|

| index | X axis max trip | 3300mm |

| Y axis max trip | 2150mm | |

| Z axis max trip | 800mm | |

| Gantry width | 4000mm | |

| Gantry height | 2300mm | |

| A axis swing angel | -120°⁓120° | |

| C axis swing angel | -400°⁓400° | |

| X、Y axis max speed | 0⁓60000mm/min | |

| Z axis max speed | 0⁓30000mm/min | |

| A、C axis max speed | 170、270°/sec | |

| X、Y axis max work speed | 0⁓30000mm/min | |

| Z axis max work speed | 0⁓25000mm/min | |

| X、Y、Z axis acceleration | 3m/s2 | |

| Station capacity | 80kg/㎡ | |

| Spindle max speed | 24000r/min | |

| Max kw | 15kw | |

| Machine size | 4.2×3.2×3.7m LHW | |

| Machine weight | 4ton |

Application

1. Wooden Molds pattern industries:

Sculpture various large non-metallic mold can be particularly suitable for any kind of wood, resins, wooden pattern model, wooden model aviation and other wooden mould.

2. Styrofoam EPS foam molds pattern industries:

Figurative/characters sculpture,animal sculpture,outdoor sculpture, modern sculpture,theme park display,3d sculptures.

3. 3D model industry:

Cars models, aerospace models, boat ship marine yacht vessels models, transportation. Spare parts of industries above

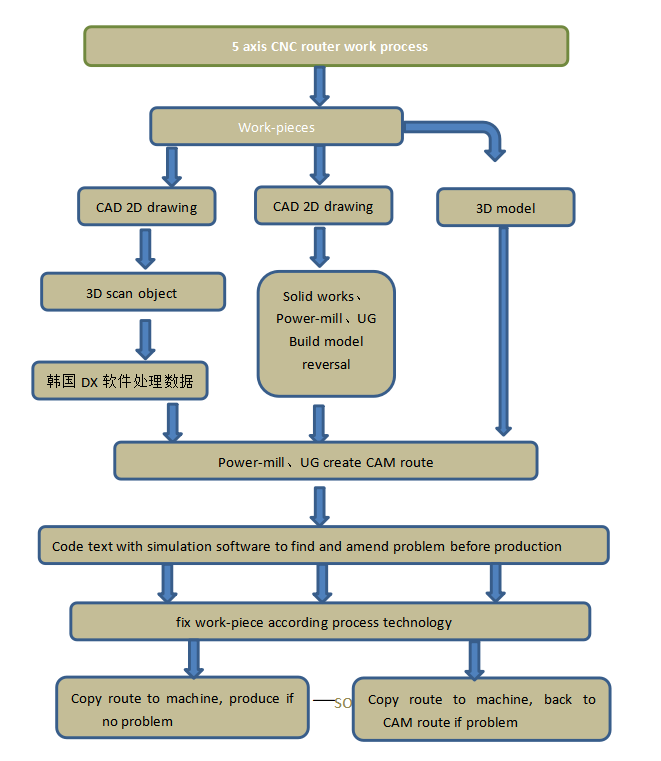

technology process

machine equipped with self-research auto avoidance software, main advantage followed: powerful function keep machine machine run in high efficiency, software possess unique function of program,emulation,optimize all together.

1. imitate real machining movement, make sure machine run in safe and high efficiency.

2. good compatibility, accept ordinary business ISO code.

3.well to edit, support any build and edit all tools, support to read and edit macro program and G code.

4. high safety, avoid crash and interference intelligently.

5.User-friendly interface, easy to learn and use modular program.

a. total true 3D emulation

Realize multi axis 3D movement emulation 100% truly. Dynamically 360 no dead angle check multi spindles and 5 axis structure including machine model, product model, fixture model and tool route

b. perfect optimized program make production more efficiency.

Can match normal CAD/CAM software(Alphacam, Cimetron, Mastercam, UG, PowerMill, Topsoil), guide in G code to imitate directly. In visible 3D emulation, sequence tool route in optimization, delete unnecessary movement. And meantime can compress and optimize ISO code, even cut down 50% machining time.

c. intelligent program in modular

Powerful function can help programmer make optimization program in short time, avoid crash intelligently, add forward or backward movement in adjacent route to avoid crash and interference. And meantime optimize machine movement, simplify complicated and redundant route by add forward and backward movement. Build any angel drilling, cutting in 5D vision easily, so can finish build and program just input size. User-friendly interface is convenient and efficient to program.

application requirement

(environment requirement )

Voltage: 350V-50HZ, compressed air 0.8Mpa, 100-200L/minute. Sealing air tanker: 0.5M3 at least.

Environment

1. workhouse temperature 0-35°C, avoid sunshine illuminate, and lamp light in workhouse.

2. To improve accuracy of products, reduce hot transformer. suggest place machine in sealing and cooling workhouse.

3. Humidity should be less 75%, machine placed far away liquid and water leak.

4. Far away dust and corrosive air.

(operator requirement)

qualified operator should master the followed operation:

1. have high ideological quality, professional ethics, work hard, can study skill intensively. Better have rich experience.

2. Expertly master kinds of operation and program. Can operate own machine correctly and expertly and program route well, so program right and optimized route, avoid malfunction by wrong program, operation or crash.

3. know well machine character, master machine regulation. Know machine character deeply and grope situation and regulation in machine running, finish daily maintenance for own machine correctly and expertly.

4. Know well operation regulation and checking content. Should know own machine regulation and operation safety, daily maintenance and standard of checking content. Location and standard of maintenance and lubrication, grease model, normal air and hydraulic pressure.

5. Deal with and record well, take careful and record any malfunction situation and signal. Emergency deal with malfunction correctly and in time if any. And ask repair person to maintain as soon as possible. Cooperate repair person to diagnose and deal with.

service guarantee

(before sale)Sales engineer with years experience make reasonable analysis and judge according your product and process. Provide professional propose.

(sale)Communication and training for technology process, machine position, installation standard, software training, electronic and air route will be talked carefully.

(after sale)From the year 2003 to now, SOAR sold thousands of machines, including South east Asia, the Middle east, Central Asia, Russia, America, Brazil etc. Engineer install and train in scene, and service by video or online. Respond fast and professionally.

For 20 years, accumulated lots of expert professional experience on customers products, month capacity,production scene, software training, standard use of machine, workhouse management, tools application, machine maintenance, safety operation. Provide application sample most of goods.

Guarantee : one year after acceptance check

(pack and deliver)Package, storage and delivery accord with long distance and loaded many times, so be strong. We afford the responsibility by inappropriate package. Forbid storage outside in wet, and storage cannot be more than 2 months, will reduce guarantee at the third month.

Spareparts

Products show

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for Best Quality CNC Fiber Laser Cutting Machine - 5 Axis 3d Double Station Mould Processing Cnc Router – FELTON , The product will supply to all over the world, such as: Hongkong, Bolivia, Congo, The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.