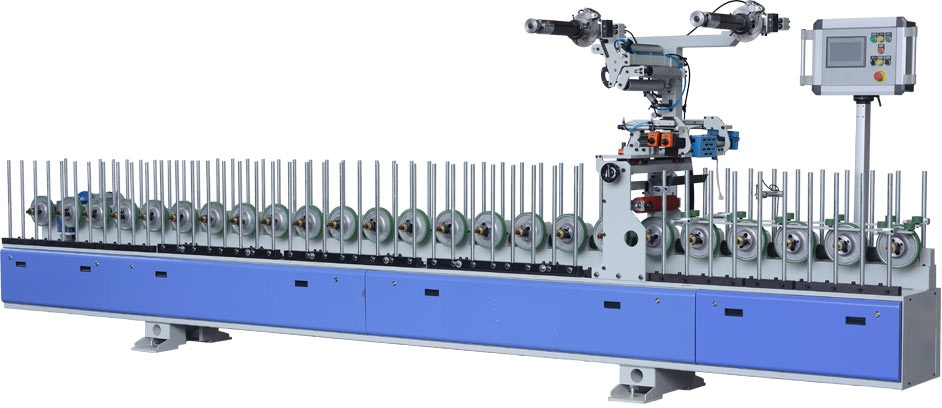

BF-45-L Multifunction Hotmelt Pur Profile Wrapping Machine

General Introduction

This machine take PUR glue wrapping the real wood, PVC film and melamine paper. It can wrap various products, such as skirting boards, set lines of door and windows, and railings of stairs. Work fast and perfect adhesive for the material.

Work Enviroment Requirement

(1)Temperature:18℃--45℃

(2)Humidity: More than 40%

(3)Voltage: 380V ± 10%

(4)Installed capacity: wrapping machine 20KW; PUR melt 12KW .total:32KW

(5)Air pressure: 6 BAR

(6)Work area equipment area:L 6M X W 2M H 3M

Feed area:7M X 2M discharge area:7M X 2M

equips and parameters

Max wrapping width 30- 450 mm

Max wrapping height 5- 90 mm

Length of machine 6 m

Drive wheels 24 sets,

Drive wheels width 15mm

Feed speed 10-50 m /min

Equips description

101 Whole steel-structure machine body, with steel plates bending and welding. Machined installation hole in high precision.

102 Drive system

24 sets drive wheels,4sets/m, 2pc/set.

2 wheels /set in width 15mm; diameter 200mm

201 Press equips Included connect bars and press wheels in set, total 120 sets

301 automatic PUR scrape coating equip, max coating width 330MM. Advantaged two-way adjustable coating system, and width showed in numbers.

401. Single air roll feed shelf. Air roll diameter 75MM, max material diameter 400MM Attached:Adjustable air break

501 Forward and backward speed controlled by frequency governor. Electrics PLC system take best motor and reducer domestically

502. separately electric box, PUR coating amount controlled by PLC, which touchable 120x90mm.

601. First press wheel are adjustable

602. Adjustable feeding ruler

Equipped at feed port, to make sure feed same speed with material.

Assist devices

1. 4 preheat hot air gun ( industrial 1600W)

2. 3 infrared lights, for preheating profiles

Heating power:1000W/PC,stainless steel surface and high temperature wire.

Equipped device

PUR melt machine

model:AutoDrum 35 (AD35 for short)

description:

Equipped for PUR wrapping, suitable for international 5 gallon bucket. This device connected by communication port with wrapping machine, provide melted PUR adhesive for profile wrapping stably.

This device take German LENZE frequency governor, best motor, and SCHNEIDER electrics.take touched mankind screen and PLC control.

Adhesive saving: just add new adhesive in box, so avoid dispensing from wipe and box, save about 1kg every buckle.

Continuous production: adhesive output from bottom of box,so wrapping work wont stop when add new adhesive.

No bubble: machine take double melt structure, adhesive output when full and stable from bottom.

Parameter:

1. Accurate calculated pump,stable pressure control system

2. standard pipe out

3. specification:20 L(5 Gallon) standard bucketed PUR adhesive

4. Bucket inside diameter:280mm (286mm adopted)

5. Melt capacity:> 20 Kg /h

6. Heating power: 5.5Kw

7. Temperature :20--180℃

8. Disc trip:0--500mm

9. Max pump speed:100rpm

10. max pump pressure:50kg/cm²

11. work pressure:0.4--0.8MPa

12. voltage:AC220V/ 50Hz

Warning system

1. overheat alarm:Heating part alarm when over top limit temperature.

2. low adhesive alarm:Light alarm when adhesive will run out.

3. pump protection: pump motor cannot start when disc below low limit temperature.

introduction of control panel

funtion and parameter of this machine set on touching screen

Start machine to open page, touch to interface

Screen show machine function parameter(work speed, quantity etc.), also can choose and fix parameters.

Touch screen includes words,numbers, icons, also touching button and number area.

Touch button: touch icon to choose function in screen(such as page up and down, counter reset).

Pop window: could open and close by touch switch directly on screen. Pop window is with catalogue, group and panel,which for introducing parameter dates.

Touch button: icon in screen r changeable which change parameter by touching.switch change everytime by touching. Such as change NO and OFF, Auto and Hand.

Number area: parameters r divided read-only and changeable. Will show a keyboard by touching changeable number,input parameter numbers and ENT for sure, or ESC for cancel.

introduction of control panel

funtion and parameter of this machine set on touching screen

Start machine to open page, touch to interface

Screen show machine function parameter(work speed, quantity etc.), also can choose and fix parameters.

Touch screen includes words,numbers, icons, also touching button and number area.

Touch button: touch icon to choose function in screen(such as page up and down, counter reset).

Pop window: could open and close by touch switch directly on screen. Pop window is with catalogue, group and panel,which for introducing parameter dates.

Touch button: icon in screen r changeable which change parameter by touching.switch change everytime by touching. Such as change NO and OFF, Auto and Hand.

Number area: parameters r divided read-only and changeable. Will show a keyboard by touching changeable number,input parameter numbers and ENT for sure, or ESC for cancel.

touch button introduction

go to next page

go to next page

back to last page

back to last page

、

、  touch to increase numbers,this icon is always with numbers, touch to increase certain numbers by every touch.

touch to increase numbers,this icon is always with numbers, touch to increase certain numbers by every touch.

、

、 touch to reduce numbers,this icon is always with numbers, touch to reduce certain numbers by every touch.

touch to reduce numbers,this icon is always with numbers, touch to reduce certain numbers by every touch.

OFF button: function parameters is off, touch to replace ON state.

OFF button: function parameters is off, touch to replace ON state.

ON button: function parameter is ON, touch to replace OFF state.

ON button: function parameter is ON, touch to replace OFF state.

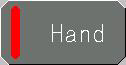

Automatic button: function is automatically, touch to replace Hand state.

Automatic button: function is automatically, touch to replace Hand state.

manual button: function is manually, touch to replace Automatic state.

manual button: function is manually, touch to replace Automatic state.

So far,touch buttons,parameters, changeable date to control machines for different work.

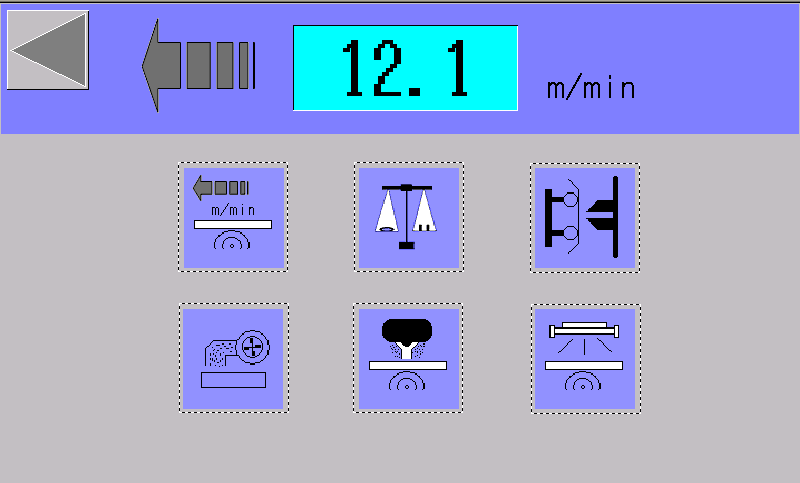

menu page introduction

it shows the set speed of machine running, touch different icons into parameters mode, and edit parameters.

drive speed: touch into speed set

drive speed: touch into speed set

amount of glue spread: touch to set  amount of glue for square meter.

amount of glue for square meter.

PUR nozzle: touch to set width of spread.

PUR nozzle: touch to set width of spread.

hot air-gun: touch to set

hot air-gun: touch to set

brush for board: touch to set

brush for board: touch to set

heating light: touch to set

heating light: touch to set

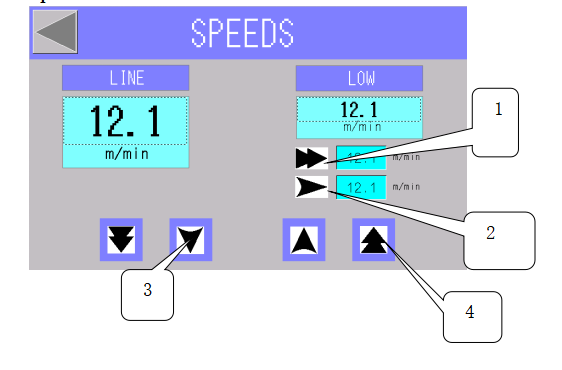

speed set interface

LINE: machine work speed

LOW: machine low speed

1、This icon is for amount of line speed, line speed increase or reduce certain amount when touch everytime.it is can touch to set.

2、 This icon is for amount of line speed increase or reduce.it can touch to set.

3、This icon is for amount of line speed reduce everytime.

4、This incon is for amount of line speed increase everytime.

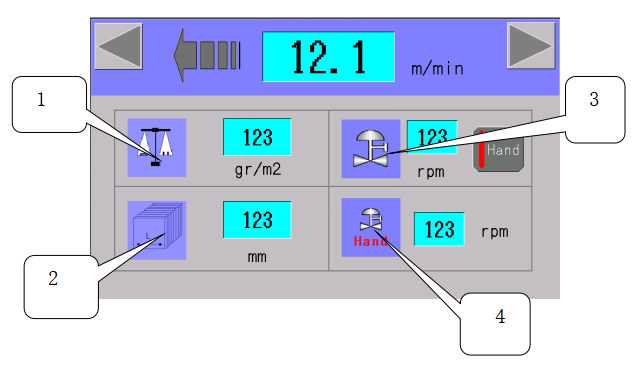

program set interface

1、PUR amount set: input PUR amount as g/m².it works only in auto mode.

2、foil width set :width range of foil,match with PUR nozzle.

3、pump speed: show pump speed in ready-only.which can change between manual and automatic mode.

4、manual pump speed:Pump speed in manual mode, touch to set.