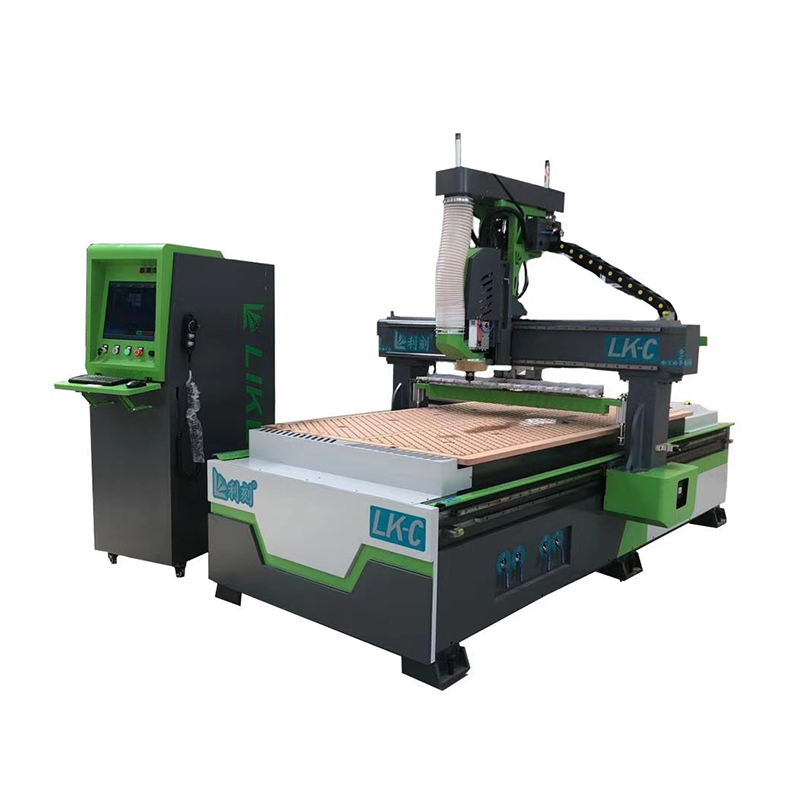

LKC Straight Atc 12 Engraving And Cutting Woodworking Cnc Router

|

LKC |

Equipped |

note |

|||

| Working stroke(X*Y*Z) | 1220*2440*300mm | ● | |||

| Spindle | Brand | HQD | ● | ||

| kw | CS9KW(ISO30) | ● | |||

| Cooling | Air cool | ● | |||

| speed | 6000-24000rpm/Min | ● | |||

| Drive system | Drive | Servo drive | ● | ||

| Drive motor | TAIWAN DELTA 1000W | ● | |||

| Servo | TAIWAN DELTA | ● | |||

| Inverter | Brand | FULING | ● | ||

| KW | 11KW adjustable | ● | |||

| Control system | SYNTEC | ● | |||

| Drawing software | ALphacam2014 | ● | |||

| Rail | HIWIH(25#) | ● | |||

| Screw | TBI32-10 | ● | |||

| Work plate | Vacuum table | ● | 4 divided area | ||

| lubrication | Automatic | ● | |||

| Foot switch |

1 pc |

● | |||

| Position cylinder |

2 for X, 3 for Y |

● | |||

| Loading assistant | Unloading device | ● | |||

| Reducer | Japan SHIMPO | ● | |||

| Rack | Taiwan helical rack (M2) | ● | |||

| Vacuum pump | Brand | LIKE specialized | ○ | ||

| KW | 9KW | ○ | |||

| Cooling | Water cool | ○ | |||

| cable | Shanghai ECHU(CE standard) | ● | |||

| Electronic control | CE standard | ● | |||

| Body structure | Enhanced with strip steelAnd milling after aging | ● | |||

| standby speed | X axis | 80m/Min | ● | ||

| Y axis | 80m/Min | ● | |||

| Z axis | 15m/Min | ● | |||

| Max work speed | X axis | 25m/Min | ● | Different for material and art | |

| Y axis | 25m/Min | ● | |||

| Z axis | 10mm/Min | ● | |||

| Tool magazines | ISO30 12 pcs | ||||

| Voltage | 380V 50/60HZ | ● | |||

| Weight | 2.3T | ||||

| Total power | 18KW | ● | |||

| Cutter instrument | ● | ||||

Write your message here and send it to us