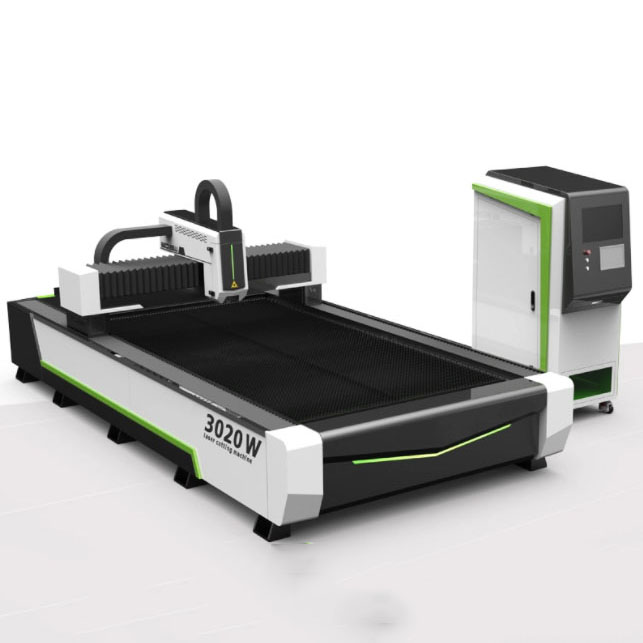

Low MOQ For Pcb Laser Engraver - Fiber metal laser pipe cutting machine – FELTON

Low MOQ For Pcb Laser Engraver - Fiber metal laser pipe cutting machine – FELTON Detail:

Material application

Carbon steel, stainless steel, galvanized steel, color steel, electrolytic plate, aluminum plate, aluminum alloy, brass, red copper, manganese steel, silicon steel, titanium plate and other metal materials.

Industry application

Kitchen appliances, sheet metal cabinet, mechanical equipment, hardware lighting, door&window manufacturing, advertising signs, auto parts, decoration, shipping and aviation, medical equipment, mining equipment and metal processing industry.

Features

(1)Fully automatic chuck can automatically center and clamp the workpiece immediately. Meanwhile, air pressure can be adjusted to ensure stable and reliable clamping force.

(2)The whole set of servo drive system imported from Japan ensures higher precision, faster speed and more stable operation.

(3)The control system is easy to operate, with more comprehensive compatibility, accurate positioning and efficient cutting.

(4)Laser: imported or domestic brand, stable performance.

(5)Humanized design makes user experience more practical.

(6)Imported electric components.

(7)Ultra low cost, low energy consumption, air assisted cutting of various metal plates.

Technical parameters

Processing format: X format φ10mm-φ 500mm, Y format 30mm-12000mm

Max. operation speed: 140m/min

Max. acceleration: 1.5G

X/Y positioning precision: ±0.02mm

X/Y repeating positioning precision: ±0.02mm

Laser power: 6000W/4000W/3000W/2000W/1000W

Working voltage: 380V, 50Hz

Operation temperature and humidity of machine tool: 0℃-40℃, <90%

Driving mode: Precision rack dual drive

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Low MOQ For Pcb Laser Engraver - Fiber metal laser pipe cutting machine – FELTON , The product will supply to all over the world, such as: Kyrgyzstan, Suriname, Russia, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.